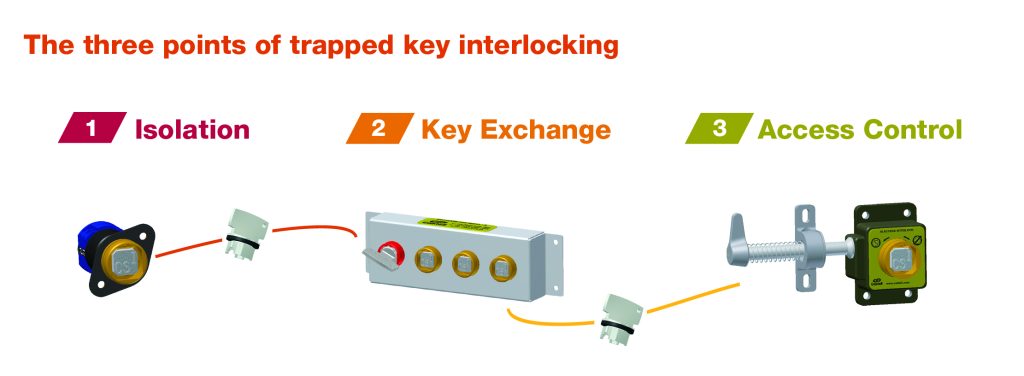

In a trapped key interlock system, an industrial process is initiated by a key retained by an interlock when the machinery is operating and the only way to remove the key is to de-energise the machine, releasing the interlock and allowing the key to be removed. The same key is then used to access an area where safety is a concern, and in this position, the key is also retained. The safety system built around the process will ensure that the machinery has come to a complete stop and all the other safety systems are functional and in place. This trapped key can then only be removed once the access gate has been closed and all the safety systems are operational, it’s then utilised to restart the process once again.

Early Beginnings

Trapped key interlocks were first utilised during the 1890s on the busy French railway network to control track switching operations ensuring they worked safely and efficiently. It wasn’t until the 1920s when Harry Castell developed the technology further to support the expansion of London’s electricity grid, creating devices to help protect valuable assets and the people interacting with them that their use became more mainstream.

Fast forward to the present day, and Castell is now part of the Halma group of companies, with subsidiaries in many countries around the world is still manufacturing the widest range of safety interlocking systems available. Hard-wearing and durable, these interlock systems have stood the test of time in all manner of harsh operating environments. Foremost, trapped key interlocks ensure that machinery and the personnel using them are kept safe from harm, even in the most demanding locations.

Improving Safety

Industrial safety has come a long way since the birth of the industrial revolution, in today’s environment ensuring the safety of operatives and service engineers of industrial machinery is paramount, not only to prevent dangerous instances from occurring but to protect the respective company from litigation. Financial incentives aside, a company that doesn’t care for its employees or the users of its industrial machinery and equipment won’t survive very long if it deals nonchalantly with the issue of safety.

Creating an environment that ensures that a safety process is adhered too and cannot be avoided is the basic functionality of a trapped key interlock system. Transferring a master key from the system used to turn on an industrial process to the safety access facility ensures that whether an operative is shutting down or starting a specific operation they are safe from potential injury.

Essentially, the key is trapped when the machine is running and access to dangerous areas is prevented, or the key that allows the machine to start is trapped while an access door is open. The use of duplicated keys could possibly lead to a circumvention of this safety process, to avoid this, duplicate keys ideally should be been stored safely offsite or require some form of specialist process to access them or require ordering from the supplier.

Kempston Controls is committed to finding you the ideal solution for your application. Call us today on +971 (0) 4 2987111, email us at sales@kempstoncontrols.ae, or alternatively contact us here, we will be happy to help.